Generation and applications of x-ray and extreme ultraviolet beams carrying orbital angular momentum

In addition to spin angular momentum, light can carry orbital angular momentum. The orbital angular momentum degree of freedom in the extreme ultraviolet and x-ray regimes enables fundamental studies of light-matter interactions and new methods to study materials. Advances in x-ray optics, as well as undulator radiation and high harmonic generation techniques, lead to the creation of beams with non-trivial phase structure, such as a helical phase structure, creating new possibilities for the use of extreme ultraviolet and x-ray photons with orbital angular momentum in probing complex electronic structures in matter.

Mixed Delay/Nondelay Embeddings Based Neuromorphic Computing with Patterned Nanomagnet Arrays

Patterned nanomagnet arrays (PNAs) have been shown to exhibit a strong geometrically frustrated dipole interaction. Some PNAs have also shown emergent domain wall dynamics. Previous works have demonstrated methods to physically probe these magnetization dynamics of PNAs to realize neuromorphic reservoir systems that exhibit chaotic dynamical behavior and high-dimensional nonlinearity.

Artificial Spin Ices and X-ray Orbital Angular Momentum

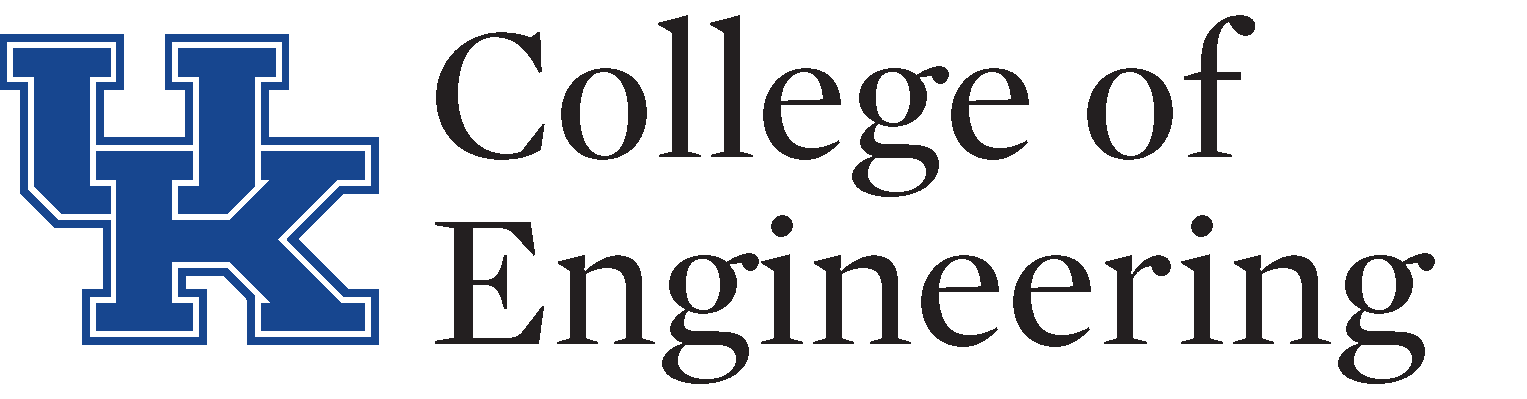

This research program seeks to understand fluctuations and phase transitions in artificial spin ices (ASIs), and to use this knowledge to study X-ray orbital angular momentum (OAM) generated by these structures. ASIs consist of patterned arrays of nanomagnets, as shown in (a) in the figure below, whose properties can be tuned based on geometry and competing interactions. ASIs are often designed to realize systems not readily accessible in nature such as geometrically frustrated magnetic lattices. ASIs can be reconfigured through a variety of field, temperature, and direct writing approaches. Control of these processes and the introduction of defects may allow ASIs to be programmed into states with useful functions such as magnetic logic or generation of X-ray OAM. OAM is a topological property of light for which the photon phase has a helical structure around its propagation axis. Interest in optical OAM is rapidly increasing in the X-ray regime where it could provide a selective probe of electronic and magnetic systems. ASIs can be patterned with topological defects and reconfigured dynamically. As a result, they offer a pathway to X-ray metamaterials for programmable OAM generation and a platform to deepen understanding of photon interactions with 2D magnetic lattices.

Experimental realization of a single-domain AF ground state in a square ASI with a double edge dislocation and resulting X-ray diffraction. (a) Scanning electron micrograph of a permalloy ASI with a topological defect consisting of a double edge dislocation. (b) XMCD-PEEM micrograph revealing the single-domain AF ground state order. The blue boxes trace out a Burgers circuit. (c) X-ray diffraction at the Fe L-edge resonance dramatically enhances vortex beams at the AF Bragg conditions (half-integer values of H and K) which carry odd-order OAM.

This research is supported by the U.S. Department of Energy office of Basic Energy Sciences under award DE-SC0016519.

Nanoscale 3D Printing and Machining with Electron Beams

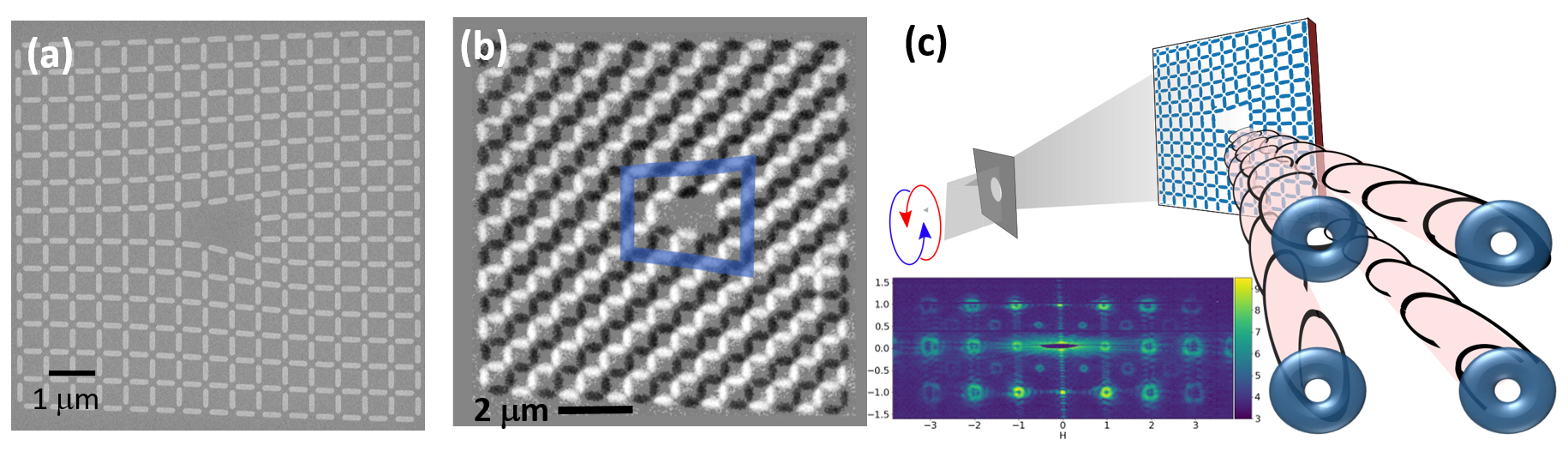

Nearly all high-throughput nanomanufacturing processes require the replication of master templates. As a result, three barriers to manufacturability demand new solutions: (1) rapid prototyping before committing to a production template, (2) repair of template errors and defects both before and during production, and (3) product debugging before committing to revised templates. Locally adding ("printing") and subtracting ("machining") materials using a focused electron-beam could meet these needs if the available materials, purity, and throughput were not limited by the associated gas-phase reactants. This research project investigates a change from gas to liquid reactants in order to expand the range of processes and materials available and dramatically improve purity and throughput. These advances could enhance efficiency at multiple points in the product cycle for nanomanufactured systems.

(a) Nanoscale 3D printing using electron-beams in liquids. An aqueous solution typically serves as the precursor and remains liquid on a cooled substrate in a partial vacuum. Inset: “UK” logo patterned in copper on silicon. (b) A copper “nested-L” structure deposited from CuSO4, H2SO4, and polyethylene glycol (aq.) was featured on the cover of Nanotechnology. (c) A cross-sectional micrograph of a high aspect ratio copper structure. (d) Silver structures deposited on silicon from an aqueous solution of AgNO3.

This work is supported by award CMMI-1538650 from the National Science Foundation. Publically available data from the research effort is available here: CMMI-1538650 Data.

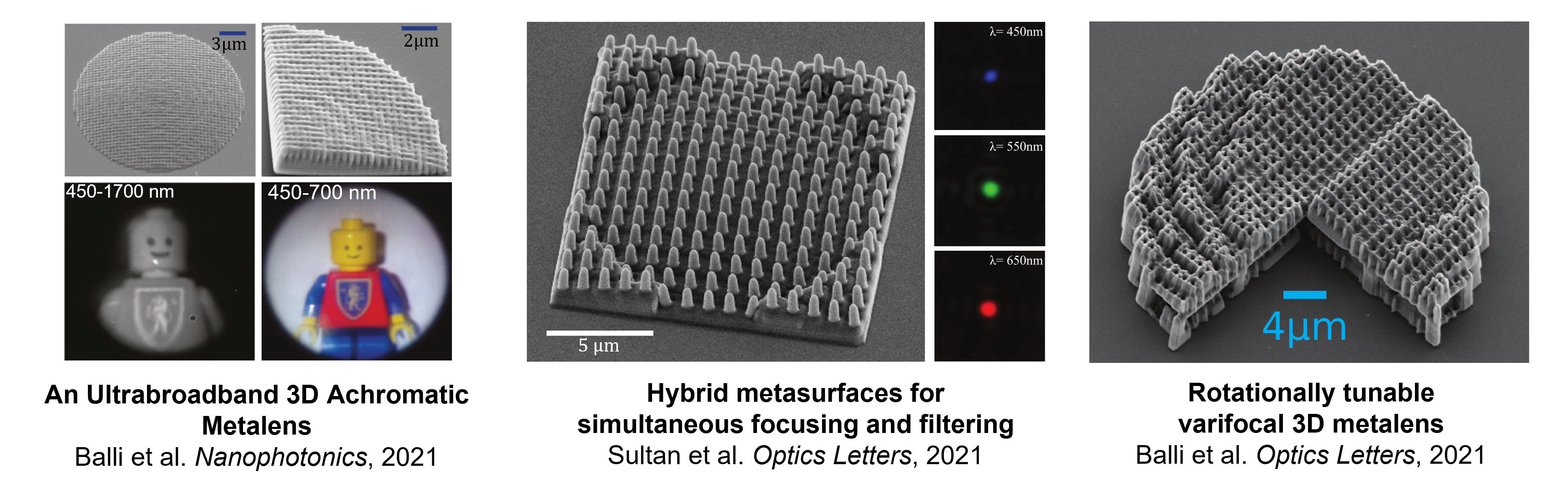

3D Optical Metasurfaces

Metalenses are nearly flat optics that employ nanostructures to manipulate light. The compact size, light weight, and mass manufacturability of metalenses make them ideal for mobile, airborne, and in-vivo imaging. In this effort we build and characterize lenses 50 times thinner than a human hair. The lenses show diffraction limited performance with light ranging from blue (450 nm) to the short-wave infrared (1700 nm). The broadband capabilities of this lens are particularly well suited to emerging visible-to-short wave infrared camera technology. A hybrid 3D architecture, which combines nanoholes with a phase plate, allows realization in low refractive index materials. As a result, two-photon lithography can be used for prototyping while molding can be used for mass production. Additional functionality, such as wavelength filtering and focus adjustment are also possible. These results show that 3D metalens architectures yield excellent performance and flexibility even using low-refractive index materials.

Clean Hydrogen Generation by Coupling Plasmonic Nanoparticles to Phototrophic Bacteria (led by Prof. Bhattacharyya, UK Chemical Engr.)

Anti-viral Membrane Masks and Filters (led by Prof. Bhattacharyya, UK Chemical Engr.)

Metasurface color filter arrays with a high efficiency and low color error

This research is to develop an alternative for achieving color images in digital cameras. The focus is using metasurfaces to provide color filtering and focusing requiring low-refractive index polymer and micron-scale patterning instead of high-refractive index materials and deep sub-micron fabrication to crate color filtering and focus. The alternate 2.4 dimensional metasurface, is capable of producing low color error while also achieving high efficiency using six independent spectra with focus on nine monocjrome pixels.